Download Certificates of Sterility: Find more information on Certificate of Sterility Downloads

Select one of the options below to begin your product search using the selector tools.

Our Brands

Tyvek® delivers comfortable and durable protective garments that protect against a wide range of chemical threats and hazards. From the cleanroom to a hazardous cleanup, Tyvek® provides the right PPE for the job.

Not all deadly threats come in the form of fires or weapons. For comprehensive protection against low levels of dangerous chemicals, to toxic gases and biological hazards, industrial workers rely on garments made of DuPont™ Tychem®.

ProShield® garments can help protect against non-hazardous dry particles and light liquid splash applications typically found in industrial situations.

Tyvek® IsoClean® garments have a long history of use in cleanrooms due to their excellent barrier to particles, microorganisms and non-hazardous liquids. They offer an ideal balance of protection, durability, comfort and contamination control.

Our Featured Products

DuPont provides industry-leading protective options designed to keep you safe on the job. From FR apparel to protective gloves and coveralls, DuPont provides unparalleled protection from the neck down.

- Tychem® 2000 SFR

A POWERFUL PROTECTIVE BARRIER

Tychem® 2000 SFR coveralls provide an effective barrier against a range of inorganic acids and bases and industrial cleaning chemicals and particles. Use SafeSPEC™ to find the right chemical protection.

- Tyvek® 800

Tyvek® 800 provides an effective barrier against many water-based inorganic chemicals in low concentration, biological hazards, and particles down to 1.0 micron in size.

- Tyvek® 500 HV

HIGH VISIBILITY - ROBUST YET LIGHTWEIGHT

DuPont™ Tyvek® 500 HV coveralls in fluorescent orange with silver grey retroreflective bands for day and night visibility offer an excellent barrier against fine particles and fibers.

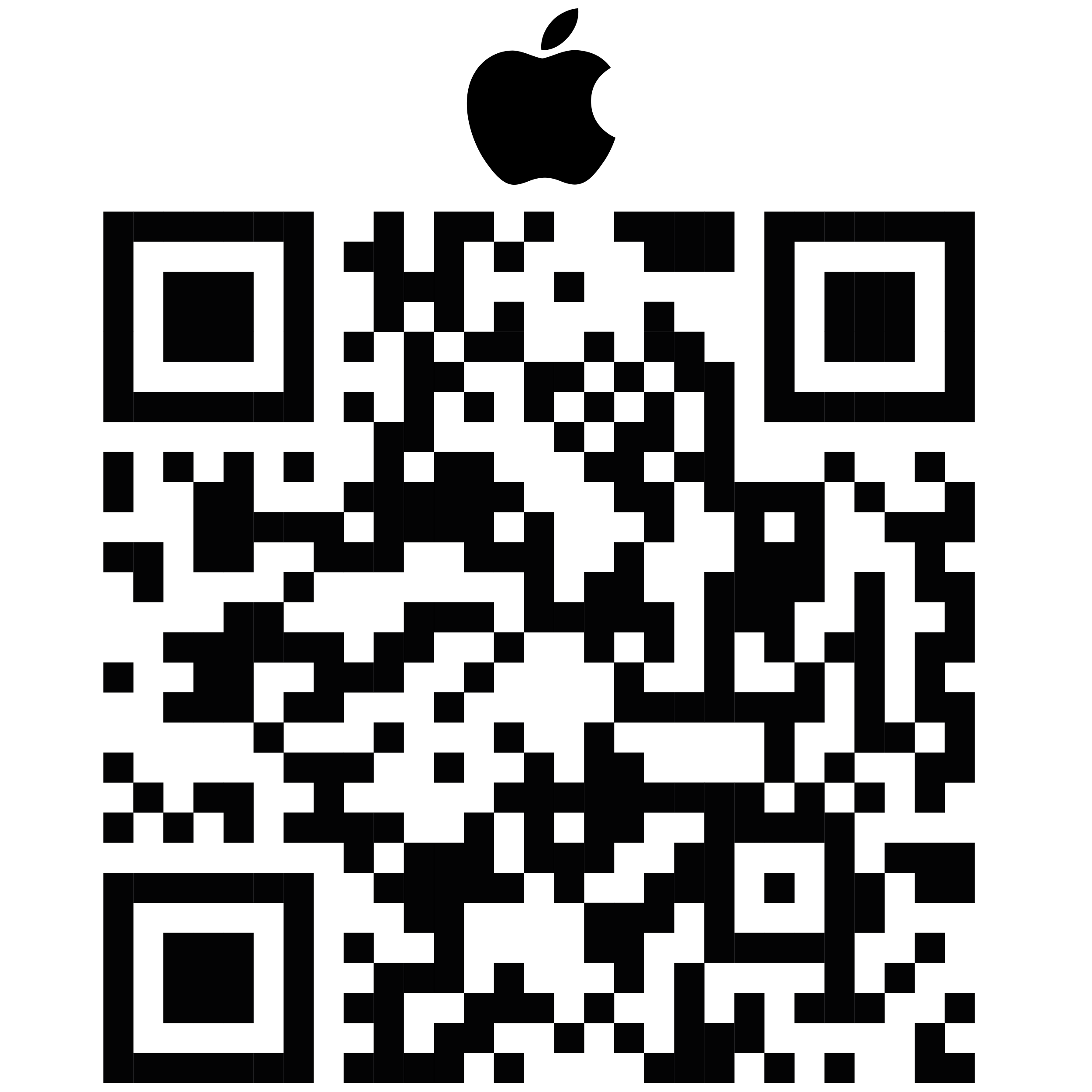

Get the free SafeSPEC™ mobile app